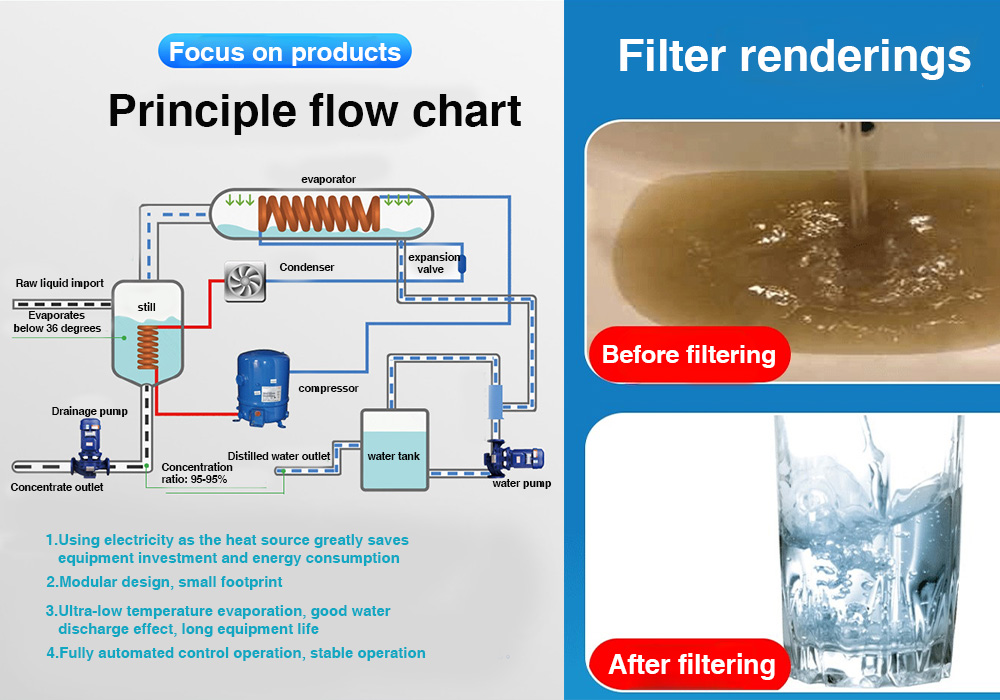

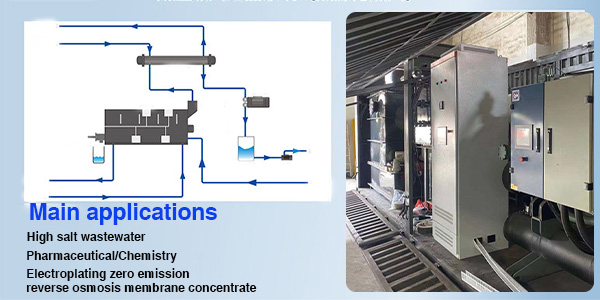

Low temperature evaporation equipment special designed for electroplating industry

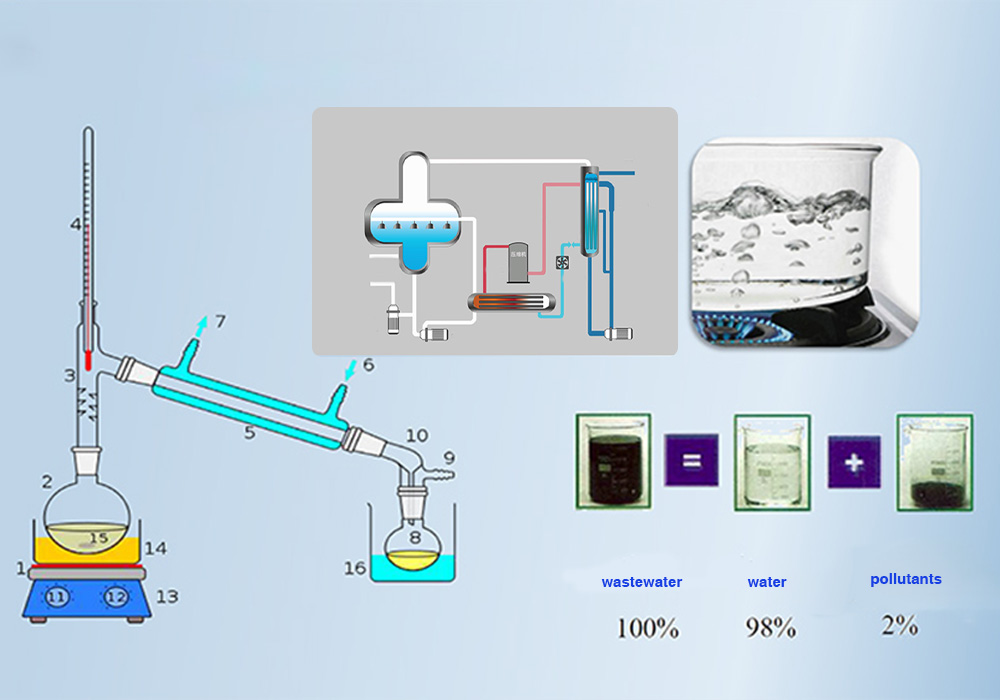

1.The equipment processes electroplating solution at room temperature without the need for preheating, and the energy consumption of the entire processing process is energy-saving compared to traditional high-temperature treatment. This equipment operates at low temperature and normal pressure throughout the entire process. The material temperature is controlled within 50 degrees, which will not cause high pressure and high temperature accidents

2. The treatment process is at normal pressure and low temperature, effectively protecting the organic compounds in the electroplating solution from denaturation, which is beneficial for the recovery of metal substances in the wastewater

3. In response to the corrosiveness of waste acid solution from electroplating enterprises, equipment uses anti-corruption materials such as PTFE/PPH/silicon carbide instead of traditional evaporator alloy materials at normal pressure and low temperature. Effectively combated corrosiveness.

4. This material is also suitable for recycling volatile and corrosion-resistant substances such as inorganic acids (nitric acid, sulfuric acid, and hydrochloric acid), strong alkaline waste liquids, or strong corrosive waste liquids generated in the chemical industry

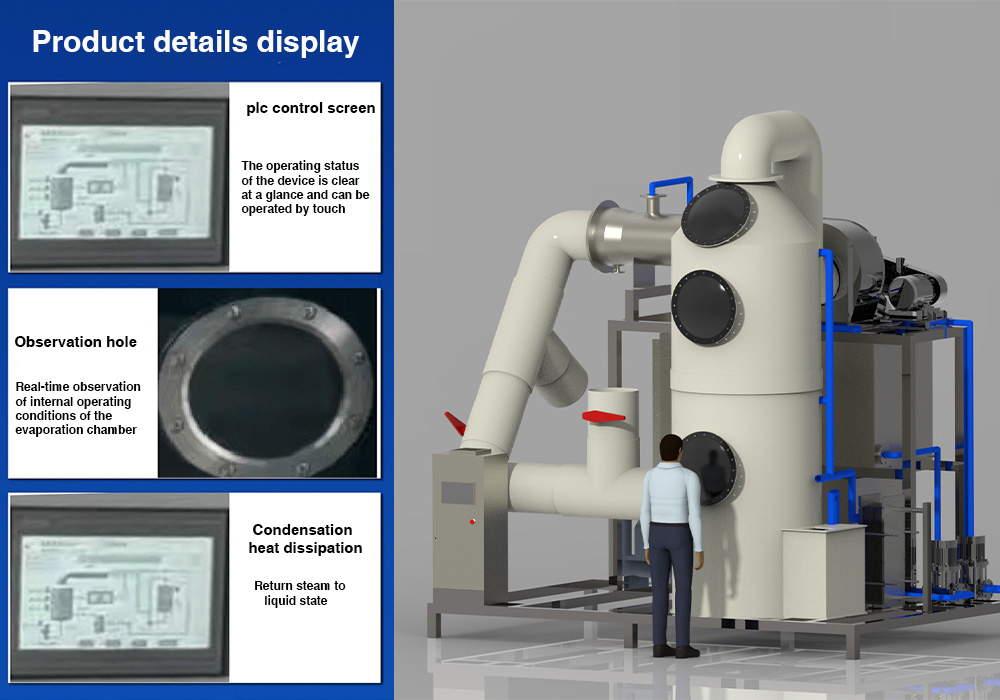

5. The device comes with a built-in cleaning function. It can avoid machine shutdown and block the highly automated design of equipment, basically realizing unmanned supervision, automatic alarm shutdown for equipment failure or system parameter abnormalities