The project details:

The project: waste sanitary landfill site leatchate treatment equipment

The treatment process: Pretreatment and the STRO(Space Tube Reverse Osmosis)

Treatment capacity: 400Ton/day

The output water standard: The effluent quality reached the limit value standard of Table 2 of the “Pollution Control Standard for Domestic Waste Landfill” (GB16889-2008)

Photos taken at site

Leachate from garbage refers to a high concentration of organic or inorganic components produced during the process of garbage stacking and landfill due to biochemical degradation such as fermentation, as well as the infiltration of precipitation and groundwater. The water quality of leachate is complex and varied, containing heavy metals and other toxic and harmful substances, and the concentration of pollutants is often tens or even hundreds of times higher than that of urban biochemical sewage. The common traditional biochemical and membrane treatment technologies have certain limitations. During the operation of garbage leachate treatment stations, there are the following problems: the amount of leachate produced during the rainy season is larger than usual, the scale of the treatment station cannot meet the production during the rainy season, the leachate is directly discharged into surface water bodies, and some leachate treatment stations are difficult to expand due to geographical location and site constraints. As the operation time of landfills becomes longer, the biodegradability of leachate from aging landfills deteriorates, the C/N ratio is severely imbalanced, the load on the biochemical treatment system becomes heavier, and the treatment cost of sewage stations significantly increases. The concentrated solution produced by the deep treatment of reverse osmosis in some landfills is re injected into the landfill area. Long term re injection leads to the enrichment of salt and organic matter in the filling material, causing blockage of the diversion pipe in the landfill area, increasing the operating cost of the treatment station, and making it difficult to meet the standards. A thorough solution for the full quantification treatment of leachate is urgently needed, which includes harmless treatment of leachate, reuse of clear liquid or discharge up to standard, solidification of tailings for harmless landfill, and completely solving the problem of leachate pollution.

At present, the composite catalytic oxidation integrated equipment developed by factory has successfully solved the problem of difficult treatment and high cost of concentrated leachate from garbage. In the traditional treatment mode, only the composite catalytic oxidation process needs to be added at the back end of the process to make the concentrated solution meet the standard, saving huge process renovation costs and making wastewater discharge meet the standard. On site introduction of this fully quantified disposal process, achieving advanced technology, reliable operation, convenient maintenance, economic rationality, environmental protection, safety and hygiene, and energy conservation, with technical and economic performance in compliance with relevant laws, technical standards, and technical specifications.

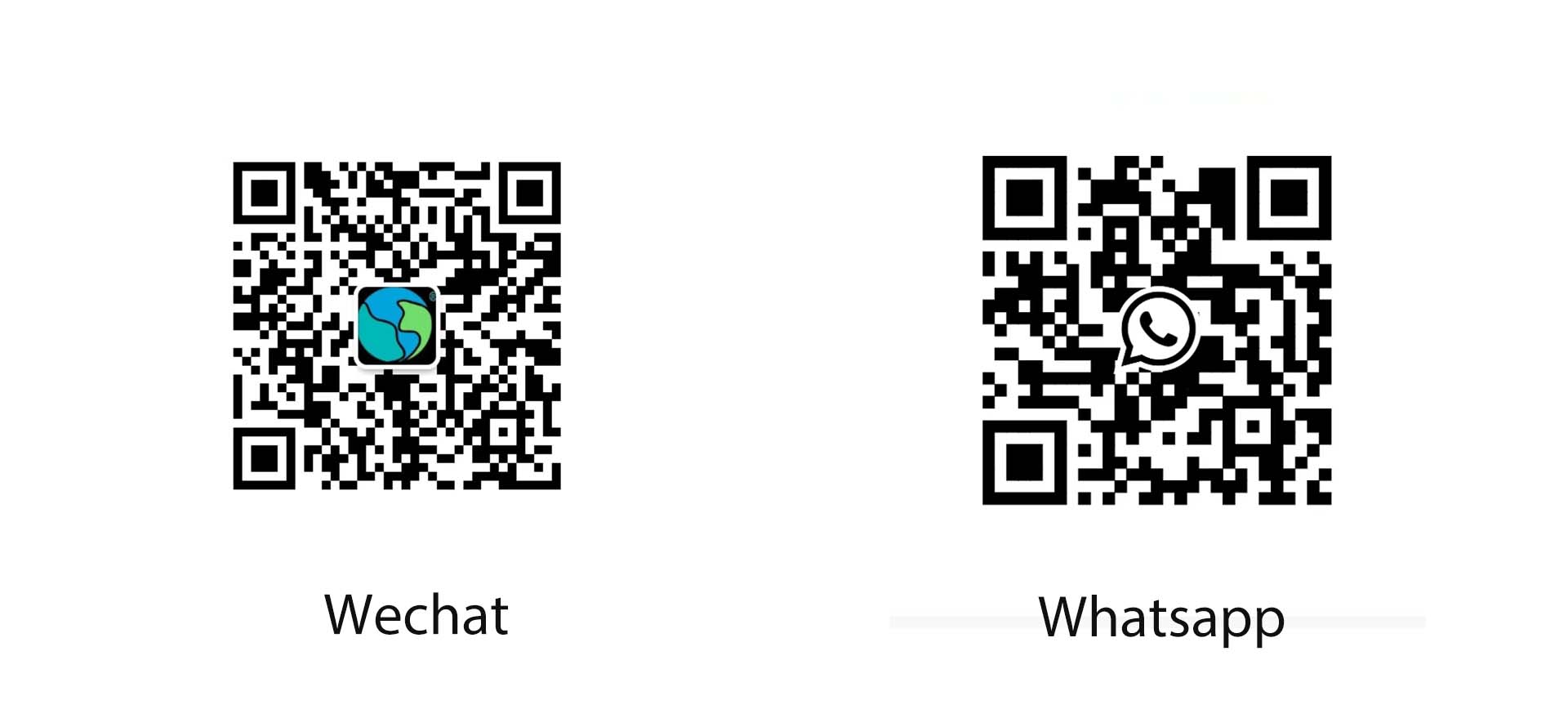

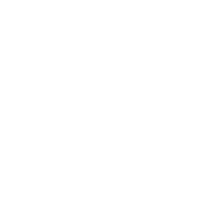

Welcome to contact us for more information.