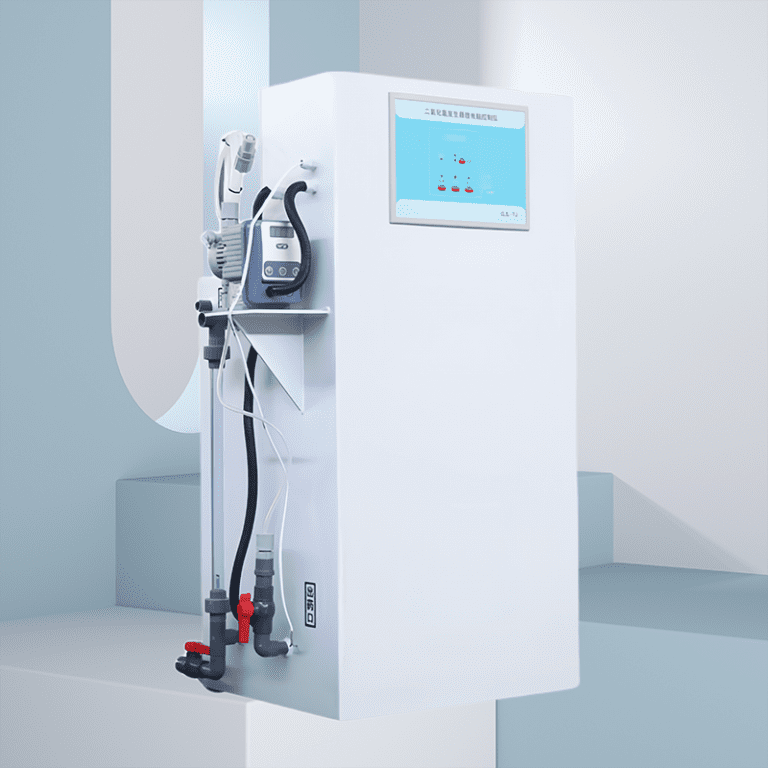

Membrane washing machine is a device used for cleaning reverse osmosis membranes, mainly used to remove dirt and impurities on the surface of reverse osmosis membranes, ensuring their normal operation and efficient filtration.

The membrane washing machine can restore 80% efficiency of the filter membrance, saving the cost for water treatment. Our factory can do the customized size and configuration according to the requirement

The working principle of a reverse osmosis membrane washing machine is to utilize the selective permeability of the reverse osmosis membrane to allow water molecules to pass through the membrane under a certain pressure, while the vast majority of inorganic salts, organic matter, bacteria, viruses, etc. dissolved in water cannot pass through the reverse osmosis membrane, thus achieving water purification. Specifically, the reverse osmosis membrane washing machine applies a certain pressure to continuously allow water molecules to pass through the membrane, while impurities such as ions, organic matter, bacteria, viruses, etc. are trapped on the inlet side of the membrane and then flow out at the outlet of the concentrated water, thus achieving the purpose of separation and purification.

Cleaning method of film washing machine:

Chemical cleaning: Use chemical cleaning agents to remove contaminants from the surface of the membrane.

Physical cleaning: Use high-pressure water flow or ultrasonic cleaning to remove contaminants from the surface of the membrane.

Biological cleaning: using microorganisms to decompose pollutants on the surface of the membrane.

The main function of the membrane washing machine is:

Removing pollutants from the membrane surface: Due to the inevitable accumulation of pollutants during membrane use, which affects membrane performance, a membrane washing machine can effectively remove these pollutants and restore membrane performance.

Extend the service life of the membrane: Regular cleaning of the membrane can effectively extend its service life and reduce operating costs.

Improving membrane efficiency: The performance of the cleaned membrane is restored, which can improve the filtration efficiency of the membrane and reduce processing costs.

Ensure product quality: The cleaned film can guarantee product quality and prevent contaminants from entering the product. Meet environmental requirements: The membrane washing machine can effectively treat the waste liquid generated during the membrane cleaning process, avoiding environmental pollution.

The environmental protection equipment membrane washing machine is mainly used to clean films used in various industrial production processes:

Reverse osmosis membrane: used for water treatment to remove salt, impurities, etc. from water.

Ultrafiltration membrane: used for water treatment to remove suspended solids, colloids, etc. from water.

Nanofiltration membrane: used for water treatment to remove organic matter, heavy metals, etc. from water.

Microfiltration membrane: used for water treatment to remove bacteria, viruses, etc. from water.

Electrodialysis membrane: used for water treatment to remove salt, acid and alkali from water.

Other industrial membranes: used for filtration and separation in industries such as food, medicine, and chemical