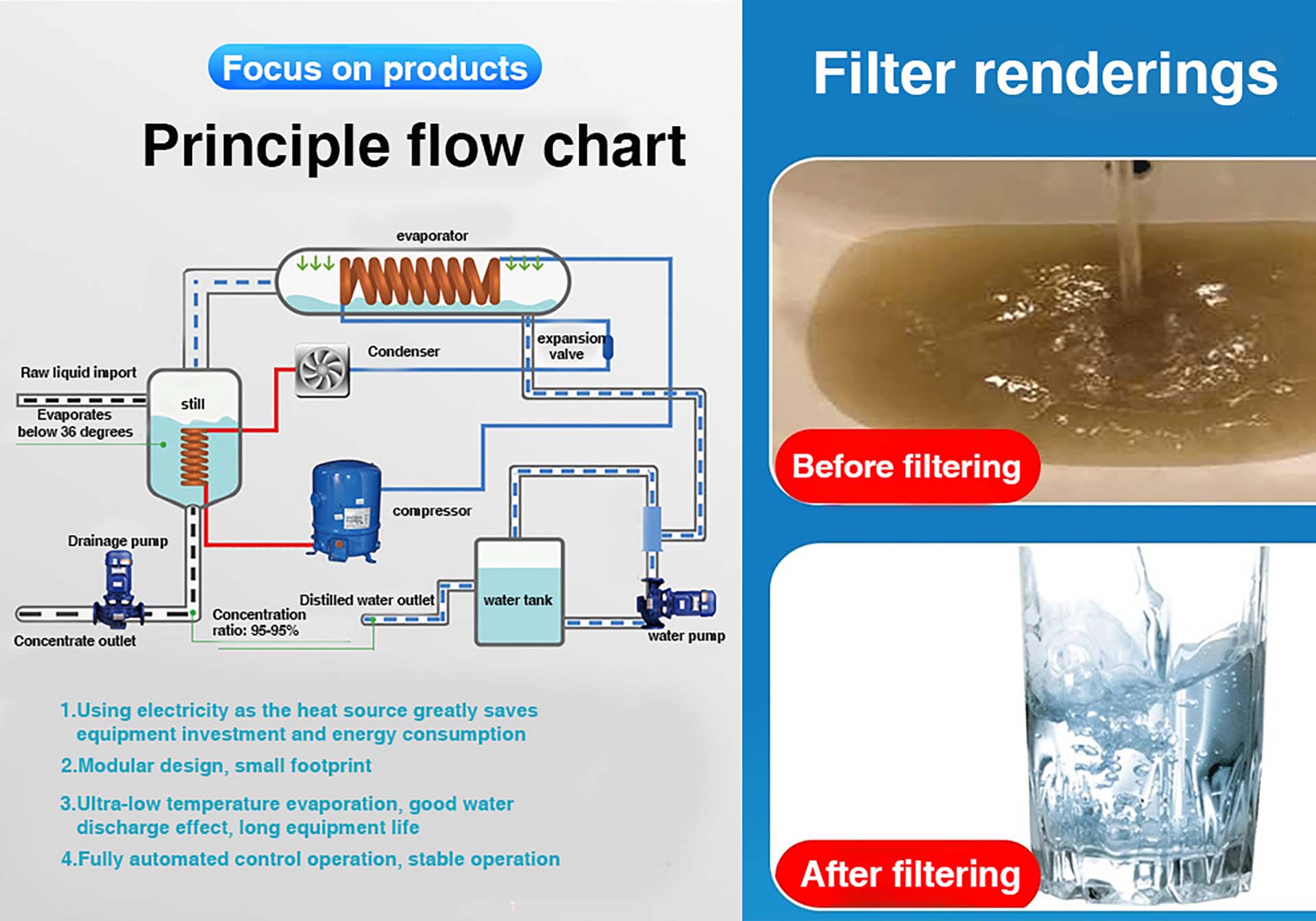

- What is the low temperature evaporation equipment?This equipment is a continuous acid regeneration system with atmospheric and low-temperature air circulation, consisting of an “air circulation system”, a “heat pump system”, and a “condensation recovery system”. It uses the low-temperature air separation degree of the air circulation system to separate water molecules and volatile substances in the acid solution. The first condensation recovery is carried out through the “condensation recovery system”, and at the same time, the “heat pump system” is used to recover the waste heat of the “condensation recovery system” to continuously provide heat to the air circulation system. The concentrated plating solution processed by the “air circulation system” is finally stored in a recovery tank for reuse. This system is suitable for the treatment of any high salt and highly corrosive solution, because the equipment manufacturing cost required for normal pressure and low temperature operating environment is low, and the recycling of waste heat circulation greatly reduces the operating cost of the equipment. It can also achieve resource recycling without damaging the organic molecules in the plating solution, while reducing the cost of hazardous waste treatment for enterprises, saving the input of plating solution raw materials, and creating tangible economic benefits for electroplating enterprises.

2. Our core technology equipment specially used into the electroplating industry. Our equipment in the electroplating industry save the cost for factory.

The solution treatment in the electroplating industry is an important issue in the field of environmental protection. As the usage time of the plating solution prolongs, the salt concentration will gradually decrease, leading to the failure of the plating solution. In addition, during the cold plating process, due to the low-temperature condensation of air, the moisture in the plating pool will increase, further reducing the concentration of the plating solution and rendering it ineffective. Faced with this situation, companies usually need to replace the plating solution or extract excess liquid, and then add main salt to restore the function of the plating tank. However, the discharged waste wave contains heavy metals and other harmful substances, and if directly discharged, it will cause serious pollution to the environment.

Our independently developed low-temperature and atmospheric pressure evaporation equipment is the solution to this challenge. The equipment can operate under low-temperature and atmospheric pressure conditions, ensuring that the organic solvents in the plating solution are not damaged and maintain their activity. Through the evaporation process, we can concentrate and reuse salt substances, truly achieving resource recovery. It can be seen that optimizing the treatment of electroplating tank waste liquid is not only a necessary measure to respond to environmental protection requirements, but also a key way for enterprises to reduce costs and improve resource utilization efficiency.

First: saves the cost of electroplating solution raw materials for enterprises

By using the evaporation concentration method for recycling and processing technology, excess or discarded electroplating solution generated during the electroplating production process can be collected. Using a corrosion-resistant low-temperature atmospheric pressure evaporator, the plating solution containing a large amount of metal salts can be concentrated to increase the metal salt content of the plating solution, and then put into the electroplating tank for use, supplementing the concentration of the plating tank.

Second: saves water for cleaning plated parts for enterprises

The mixture of water extracted by the evaporation device and surface active agent can be used as cleaning water for the plated parts before entering the plating tank, because the water extracted by the evaporation device comes with surface active agent, which plays a good role in cleaning the surface of the plated parts, and the components come from the plating tank. The residue on the surface of the plated parts after cleaning will not have any impact on the plated parts, because the cleaning water is a byproduct of the concentration of the plating solution, which saves the cleaning water for the plated parts.

Third: reduces the amount of hazardous waste generated by enterprises

Traditional electroplating wastewater treatment involves the addition of reducing agents, acids, alkalis, oxidants, and other chemicals, resulting in a wide variety of substances and complex compositions in electroplating sludge. Electroplating sludge is a solid waste that is inevitably generated during the wastewater treatment process of electroplating plants, and it is also a major reason for the high production costs of enterprises. The use of low-temperature and atmospheric pressure evaporation technology can significantly reduce the generation of hazardous waste, saving enterprises the high cost of hazardous waste transfer and treatment.

3. Why choose our equipment:

(1) Compared with the traditional equipment, our equipment can reach 2 T/D the waste water treatment, meets more customer’s requirement

(2)In response to the corrosiveness of waste acid solution, the equipment adopts anti-corruption materials such as PTFE/PPH/graphite/silicon carbide instead of traditional evaporator alloy materials under normal pressure and low temperature conditions, with the best corrosion resistance effect

(3) Compared with traditional equipment, our equipment working at low temperature but normal pressure, saving the operation and commissioning cost

(4)The equipment is designed with high automation to achieve automatic alarm and shutdown for unattended equipment failures or system parameter abnormalities

(5)The temperature of the equipment entering the plating solution is room temperature, without the need for preheating in advance, greatly reducing energy consumption

(6)High operational flexibility and wide application range: Due to the fact that the main body does not require the use of metal materials, the application range of this technology can be greatly expanded, such as the recovery of volatile and corrosion-resistant substances such as inorganic acids (nitric acid, sulfuric acid, and hydrochloric acid), strong alkaline solvents, or strong corrosive waste liquids generated in the chemical industry

4. About our factory

As a sewage treatment company, Guanya Environmental Protection has been committed to providing one-stop solutions for industrial wastewater treatment. The company is located in Jieyang City, Guangdong Province. Guanya has conducted in-depth research on the electroplating industry and invested a lot of funds and manpower in the research and development of resource recycling and utilization technology in the electroplating industry. After five years of continuous testing, Guanya has finally developed an integrated electroplating tank solution, which rationalizes the drawbacks of traditional treatment equipment currently available on the market. Our company has launched two installation solutions for this equipment: integrated installation and factory floor installation. No need to modify the original production line, easy installation, small footprint, and can be used immediately upon introduction. The processing process does not require neutralization or addition of any chemicals, and the cost is lower than traditional evaporation equipment, making it durable and long-lasting.