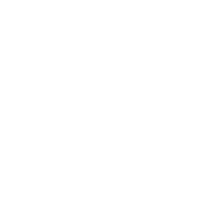

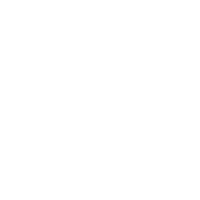

Microelectrolysis reactor is a device that utilizes the principle of metal corrosion batteries for wastewater treatment. The basic principle is to form countless fine primary batteries in acidic wastewater through the potential difference between iron and carbon particles. These primary batteries use iron with low potential as the negative electrode and carbon with high potential as the positive electrode, and undergo electrochemical reactions in the wastewater. During the reaction process, iron is corroded and converted into divalent iron ions, which enter the solution. At the same time, new ecological [H] and Fe2+are produced, which can undergo oxidation-reduction reactions with many components in the wastewater, destroying the chromophores or assisting groups of organic pollutants, and achieving the goal of removing COD, chromaticity, and heavy metal ions.

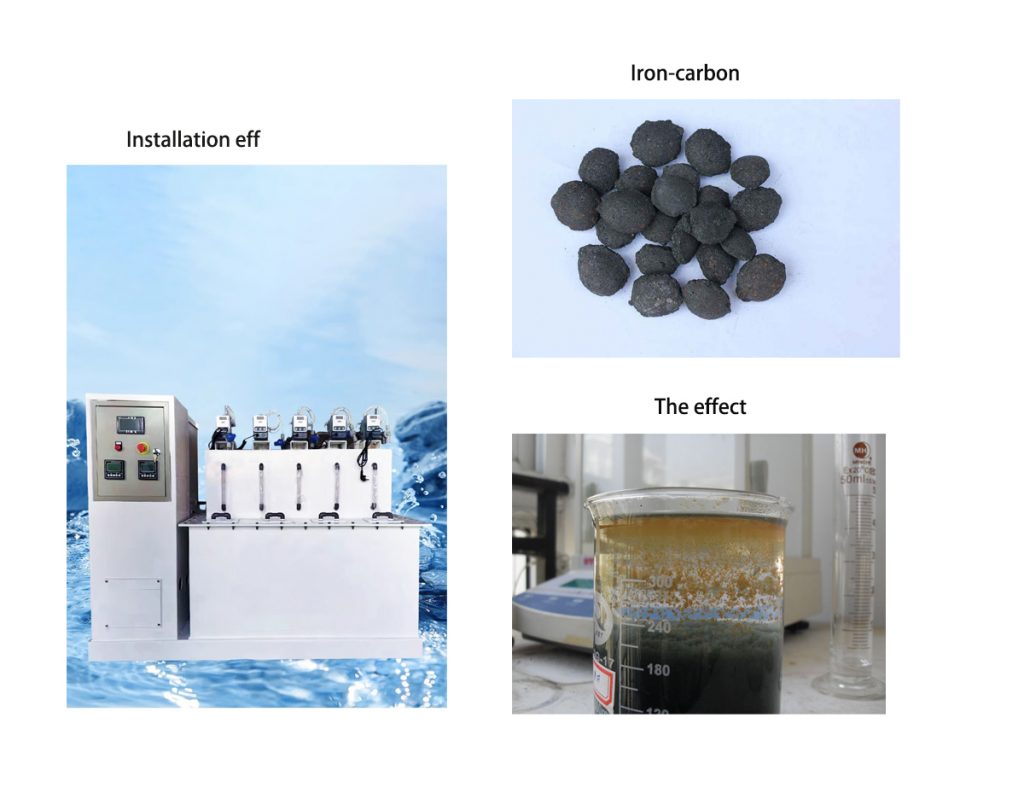

Microelectrolysis reactors have the advantages of fast reaction speed, good treatment effect, long service life, convenient operation and maintenance, and can effectively improve the biodegradability of wastewater, creating favorable conditions for subsequent biochemical treatment. Therefore, micro electrolysis reactors are widely used in the treatment of various difficult chemical wastewater, such as pharmaceutical wastewater, pesticide wastewater, dye wastewater, coking wastewater, etc.