The waste water treatment used for the dyeing industrial, daily treatment capacity 2000Ton/day.

We provide the one stop service including the waste water treatment equipment solution, equipment manufacturing, install guide and adjusting, operation guide and maintence with our professional engineer team.

There are many methods in treating the sewage waste water from the dyeing industrial for the membrane technology:

Microfiltration (MF) and ultrafiltration (UF):

The pore size of the microfiltration membrane is between 0.1 and 10 μ m, and the pore size of the ultrafiltration membrane is between 0.001 and 0.02 μ m. By physical screening, suspended particles, colloids, bacteria, and some dye molecules are removed from wastewater. Microfiltration and ultrafiltration are commonly used for the pretreatment of printing and dyeing wastewater, removing most of the suspended solids and some organic matter in the wastewater, and reducing the turbidity and chromaticity of the wastewater. For example, the color and COD removal rates of microfiltration membranes for printing and dyeing wastewater can reach 99.5% and 69.8%, respectively.

Nanofiltration (NF):

The pore size of nanofiltration membrane is generally 1-2 nm, and the molecular weight cut-off is between 0.2 and 1 kDa. By utilizing the selective permeability of the membrane, it has a high retention rate for organic matter and high valence ions. Nanofiltration membranes can effectively remove dyes and some organic matter from printing and dyeing wastewater, and the effluent quality can meet the standards for enterprise reuse. For example, after treatment with a chemical flocculation nanofiltration membrane system, the COD of the effluent from the printing and dyeing wastewater can be reduced to 100 mg/L.

Reverse osmosis (RO):

The pore size of the reverse osmosis membrane is less than 1 nm, mainly utilizing the selective permeability of the membrane to separate solvents and solutes, removing dissolved organic matter, salts, and chromaticity from water. Reverse osmosis membrane can treat printing and dyeing wastewater to a water quality close to pure water, and the effluent can be reused for high demand processes in printing and dyeing technology. For example, using biochemical and physicochemical pretreatment reverse osmosis membrane to treat printing and dyeing wastewater, the effluent meets the requirements for production water.

Membrane bioreactor (MBR):

Combining biological treatment and membrane separation technology, organic matter in wastewater is degraded by microorganisms, and suspended solids and partially dissolved organic matter are removed by membrane separation. MBR has high COD and chromaticity removal efficiency for printing and dyeing wastewater, and has strong impact resistance. For example, when A/O membrane bioreactor is used to treat printing and dyeing wastewater, the removal rates of COD and chromaticity can reach 95% and 90% respectively.

To use the membrane technology, there are many advantages compare to the traditional dyeing waste water treatment:

- Efficient removal of pollutants:

Membrane technology can effectively remove organic matter, chromaticity, turbidity, and hardness from printing and dyeing wastewater. For example, the COD removal rates of ultrafiltration and nanofiltration for printing and dyeing wastewater can reach 66% and 90.2% respectively.

2. Stable and reusable water quality:

The water quality of the printing and dyeing wastewater treated by membrane is stable and can be directly reused in the printing and dyeing process, reducing the use of fresh water. For example, the effluent after reverse osmosis treatment contains almost no organic matter and color, and can be reused for light dyeing processes.

3.Reduce the use of chemical agents:

Membrane technology does not require a large amount of chemical agents, avoiding secondary pollution.

4.Energy saving and economy:

Membrane technology has simple operation, low energy consumption, and can recycle dyes and printing and dyeing auxiliaries, which has certain economic benefits.

5.Strong impact resistance:

Membrane bioreactor and other technologies have strong adaptability to changes in water quality and quantity of printing and dyeing wastewater.

Membrane wastewater treatment equipment has significant advantages in the treatment of printing and dyeing wastewater, which can effectively remove pollutants, improve water quality, achieve wastewater reuse, while reducing the use of chemical agents and lowering treatment costs.

We provide the customized solution according to the raw water situation, welcome to contact us for the solution.

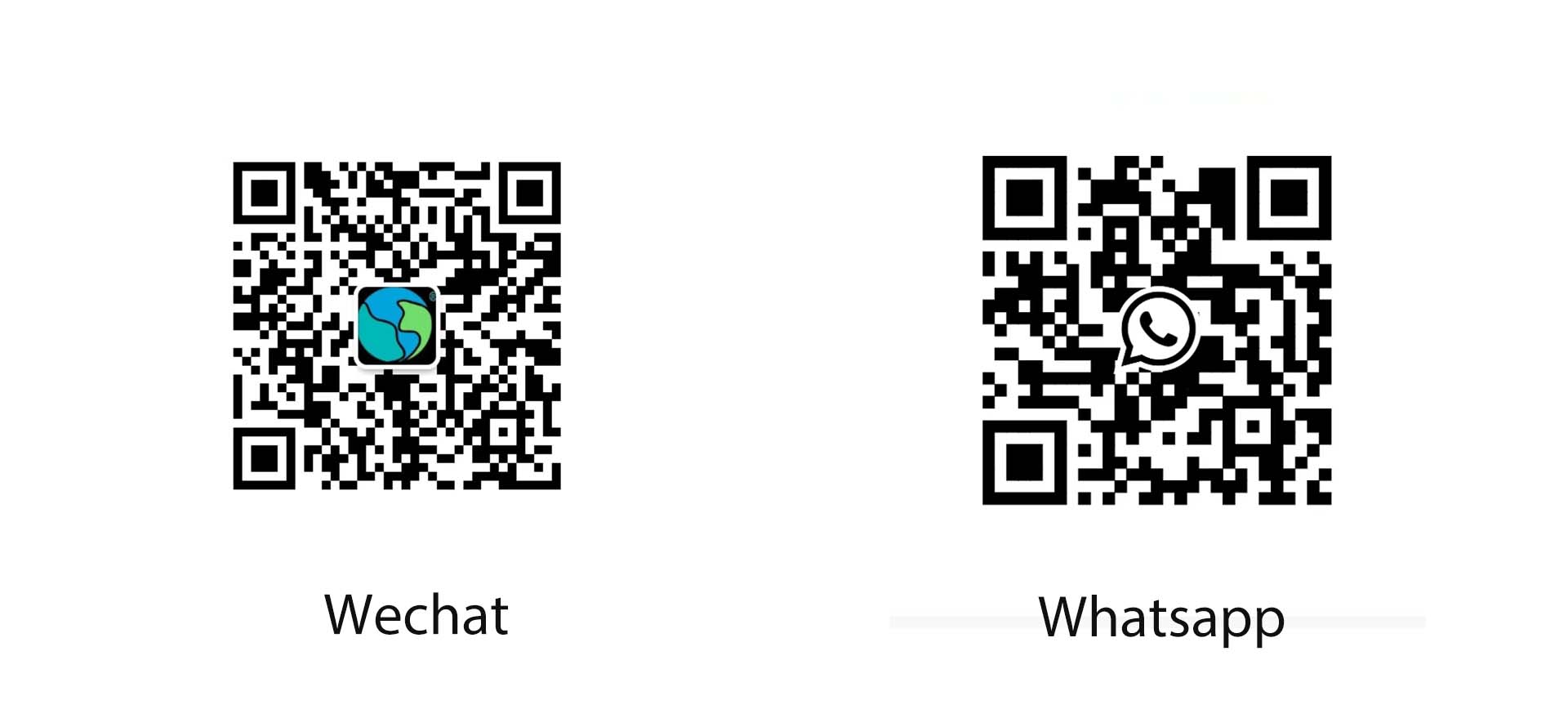

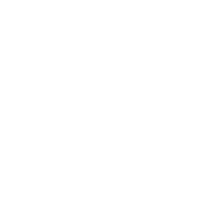

Email: export@guanyahb.com; Tel/Wechat/Whatsapp:+8619926725289.